Our Services

Hot Bitumen & Felt

Often used in paving for roads, airport runways & car parks, heated bitumen is also commonly applied to many roofs with layers of felt.

Bitumen is a substance few of us are familiar with but which many of us live within just a few feet of. Obtained naturally or as a residue from distilled petrol, bitumen is an oil-based element applied hot to roofs to bond roofing membranes to themselves and insulation materials as well as layers of vapor control to a variety of substrates.

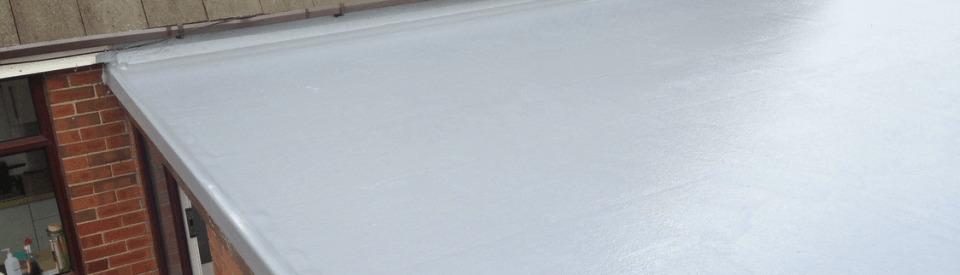

Our trained operatives here at Rooftech carefully apply hot bitumen in front of the felt roofing roll which is then unrolled into the bitumen, spreading it to give a continuous coating for the full width. The felt, typically bonded by three layers, is bedded with the hot bitumen on top of the structural roof, resulting in the creation of a waterproof system ideal for garages, sheds and small extensions.

40 years ago, the use of pour and roll hot bitumen and mineral felt began to replace sheet metal and asphalt on modern buildings as a cheap, fast-track alternative to the more expensive, traditional flat roof systems.

Now, however, the current range of materials available to our Rooftech team is far superior to those typically used 30 years ago. A life span of 7-15 years for the older, traditional felts has increased to a guaranteed life span of 20 years thanks to the modern materials, with some properly-installed felt roof systems achieving at least a half century.